APPLICATIONS

AMORPHOUS METAL GEARS

PLANETARY GEARBOXES / HIGH MODULE GEARS (ISO 3 PRECISION)

STRAINWAVE GEAR FLEXSPLINES

Strain wave gears, known for their compact size and zero-backlash performance, are crucial components in robotic arms and precision-motion systems. A key part of their function is the flexspline, a flexible, thin-walled component with precise gear teeth, though it traditionally drives up manufacturing costs. Amorphology’s innovative use of amorphous metal precision molding revolutionizes this process, enabling the cost-effective production of flexsplines with machining-level tolerances, enhancing both performance and affordability in advanced motion systems.

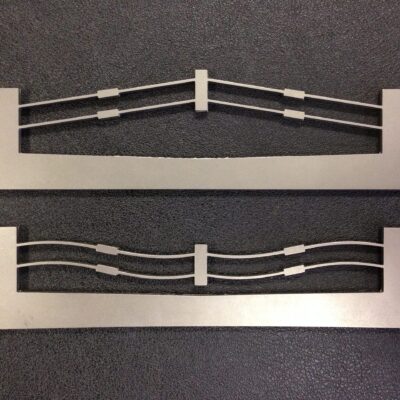

SPRINGS & COMPLIANT MECHANISMS

Compliant mechanisms, which rely on elastic deformation for precise movement, are essential in industries such as aerospace, optics, bio-implants, and sporting equipment. Amorphous metals (BMGs) elevate these applications with their exceptional elasticity, boasting a strain limit of 1.5-2%—far surpassing traditional spring materials like steel and titanium. With low damping properties, these advanced materials enable highly efficient elastic energy storage and release, making them the ideal choice for cutting-edge mechanical and structural innovations.

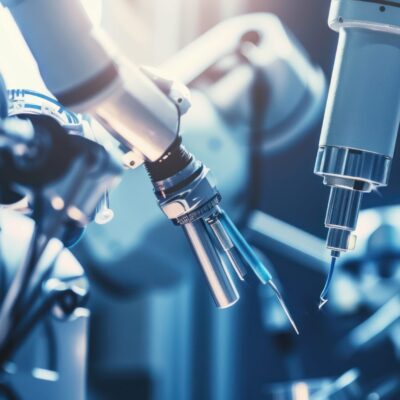

SURGICAL INSTRUMENTS

Biocompatible amorphous metal alloys are unlocking new possibilities in medical technology, offering versatile properties ideal for surgical robots and precision instrumentation. Through advanced precision molding, these materials can be manufactured with exceptional accuracy and detail, surpassing the capabilities of metal injection molding (MIM). This innovative process not only ensures high-performance components but also significantly reduces costs compared to traditional machining, making cutting-edge medical solutions more efficient and accessible.

ELECTRICAL CONNECTORS

Amorphous metals are revolutionizing electronic connector design by enabling downsizing without compromising strength, perfectly aligning with the industry’s miniaturization trends. Zr-based amorphous alloys, with their non-magnetic properties and ultra-elasticity, are ideal for sensitive applications that demand precise and reliable connector mating. Amorphology’s precision molding technology further enhances this innovation, delivering cost-effective, high-precision production of intricate connectors that surpass traditional machining in both performance and efficiency.

PAINT ROBOTS

Rotary atomizers are essential in industrial painting, using high-speed spinning cups or discs—ranging from 10,000 to 60,000 RPM—to finely atomize paint for superior finishes. Amorphology’s precision molding technology takes this to the next level, producing net-shape bell cups with mirror-like finishes and CNC-level tolerances, ensuring optimal performance. By leveraging amorphous metals, these components gain exceptional strength, elasticity, and wear resistance, outperforming stainless steel and titanium in durability and impact resistance. This advanced material innovation not only extends the lifespan of rotary atomizers but also enhances the overall quality and efficiency of industrial painting processes.