CAPABILITIES

Amorphology leverages the superior attributes of BMGs using advanced manufacturing technologies such as injection molding, additive manufacturing, and coatings to build a variety of complex components and gears.

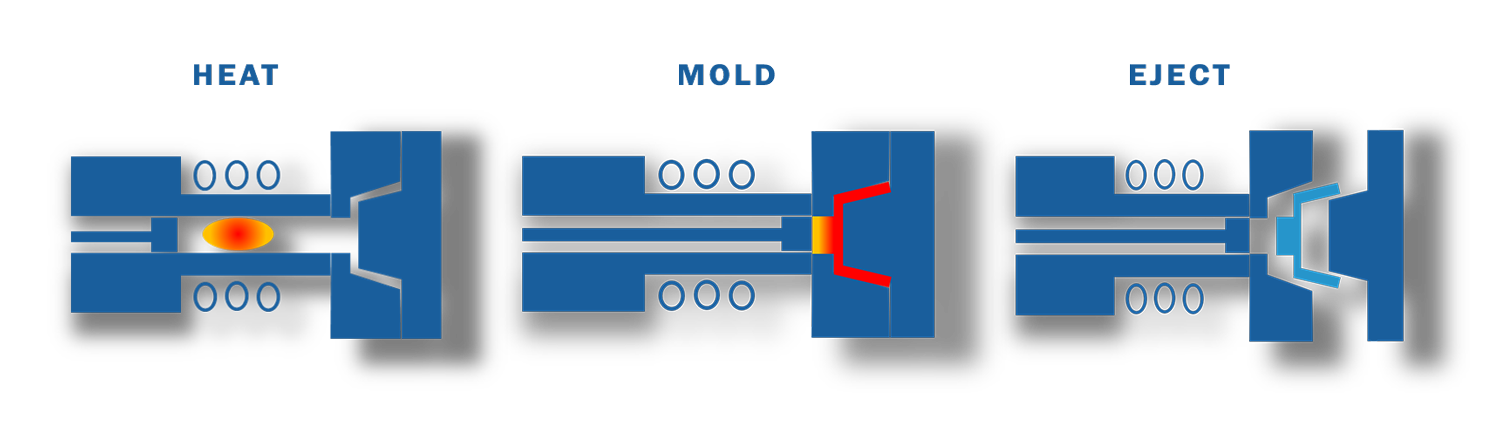

Injection molding SIGNIFICANTLY REDUCES production costs while simultaneously allowing us to create precision parts in a single step, ELIMINATING or reducing costly machining steps.

Located in Pasadena, CA where we have our vertically integrated manufacturing & development center. We cover everything from design, alloying, mold creation, injection mold manufacturing, gearbox testing and inspection/quality control.

INJECTION MOLDING

Amorphology is the first company to develop the commercialization of bulk metallic glass flexsplines for strain wave gears, planetary gears and other precision gearboxes and precision components. We have cut production time dramatically by using injection molding while maintaining a micron level of precision.

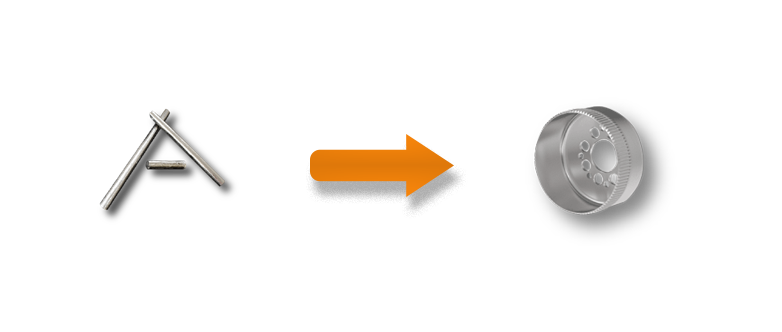

MACHINING & DESIGN

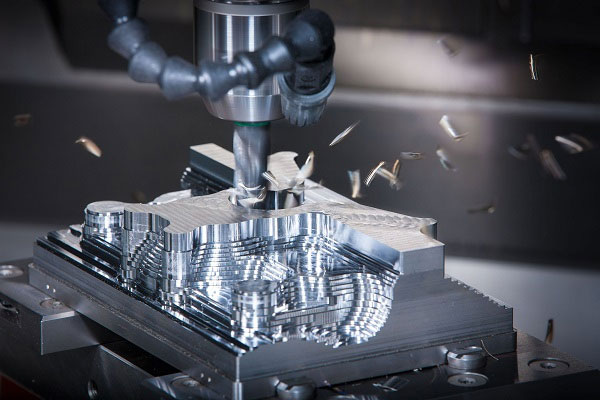

Our in-house, high-precision machining capabilities give us the ability to manufacture component molds for injection molding with quick iteration as needed.

In addition, we can rapidly prototype high-precision BMG components by machining from our BMG blanks.

As required by the high-precision parts we can produce, our machining capabilities can reach micron-level tolerances.

- 3-axis, 5-axis and 7-axis CNC mill-turns.

- Microwire EDM (Down to 0.00079inch/0.02mm)

- Up to 200mm-cube in size

- Water jet cutting machine

TOLERANCE CHARACTERIZATION & QUALITY CONTROL

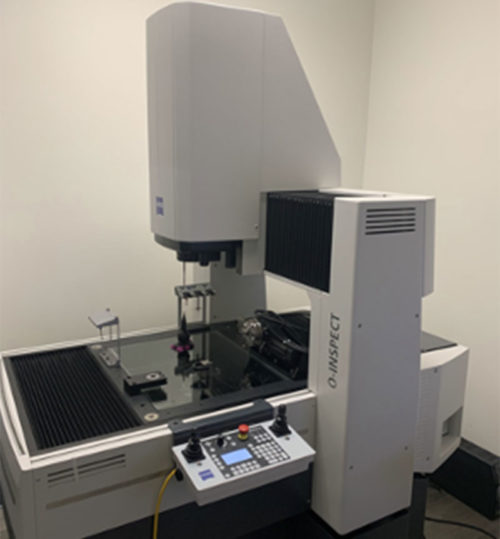

Amorphology has a dedicated temperature-controlled CMM room to measure precision tolerances for the part we produce. Staffed with expert CMM operators and gear engineers, we’re able to assess molds and parts the same day they are produced.

- Tactile inspection and optical inspection of a variety of different geometries.

- General inspection and gear specific CMM instruments.

- Repeatable measurements of tolerances in the micrometers.

GEAR MODELING & DESIGN

Rapid prototyping opens the door for quick design iterations that would be challenging to effect in a mold. This way, the customer can make sure the parts fit their specific tolerances before purchasing.

At Amorphology, we have a variety of bulk metallic glass (BMG) gear projects and Functionally Graded Material gearbox projects which involve gear design, modelling, inspections and sometimes reverse engineering.

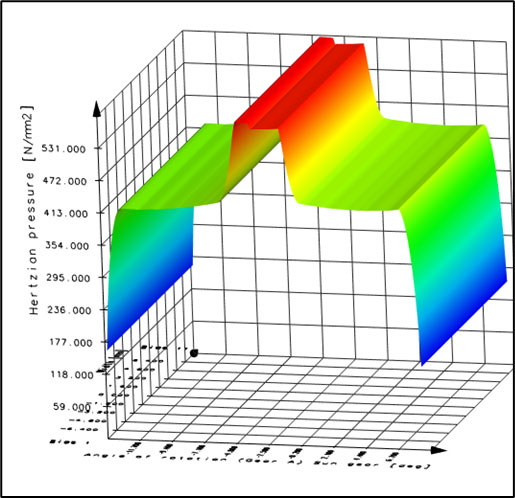

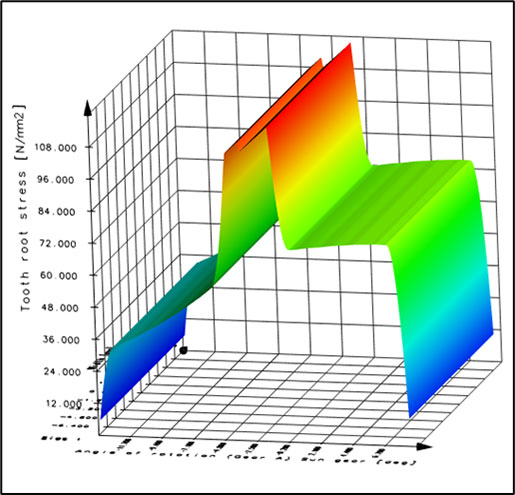

Partnering with KISSsoft (KISSsoft AG), part of multi-national Gleason Corporation, has been crucial for us as a start-up working on gearbox’s. Thier modular calculation program for the design, optimization and verification of gears helps us in several of our ongoing planetary gearbox projects. Understanding the contact stresses in various regions of the gear really help us tailor the best alloy for the application and enable us to make design modifications as needed.

These two plots show examples of plots from a planetary gearbox we’re fabricating.